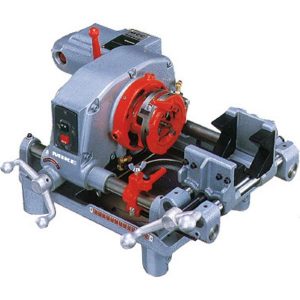

REMS Magnum 4 threading machine up to 4″, made in Germany

SKU: Magnum 4versatile, high-performance threading machine featuring maintenance-free operation, multiple motor options, and advanced safety and lubrication systems for a wide range of industrial applications.

REMS Magnum 4 inch threading machine is a robust and compact high-performance tool ideal for precision threading, cutting, deburring, nipple threading, and roll grooving. It accommodates pipe threading from ½ to 4 inches and bolt threading from 20 to 60 mm, making it suitable for installation, metalworking, and industrial tasks in both on-site and workshop settings.

This machine boasts a maintenance-free gear system that operates within a sealed oil bath, ensuring high efficiency and reducing downtime. For safety, it is equipped with a foot switch featuring an emergency stop, enhancing operator protection. The self-tightening quick-action hammer chuck guarantees no pipe slippage, providing secure clamping, especially for longer pipes, complemented by a rear centering device for accurate material alignment.

|

|

|

| 380442 & 344150 | 380442 & 344100 | 380442 & 344105 |

REMS Magnum 4 threading machine up to 4″

An automatic lubrication and cooling system prolongs the life of the dies, tools, and machine by maintaining clean threads. The universal automatic die head accommodates all thread sizes, including long threads, and features an automatic opening with a thread-length stop for tapered threads. Toolsets for 1/16 – 2″ and/or 2½ – 4″ threading include all necessary equipment, ensuring a broad range of applications.

– Threads pipes from ½ to 4 inches (16 – 63 mm).

– Threads bolts from 20 to 60 mm (½ – 2 inches).

– Maintenance-free gear system within a sealed oil bath.

– Safety foot switch with an emergency-stop function.

– Self-tightening quick-action hammer chuck to prevent pipe slippage.

– Rear centering device for accurate material alignment.

– Automatic lubrication and cooling system for longevity.

– Universal automatic die head for all thread types, including long threads.

– Option of three powerful motors for tailored performance.

– L-T version for mobility with a removable oil basin and chip tray.

– T* version for a fixed setup with an integrated larger oil basin and chip tray.

Customers have the choice of three powerful motors, with the L-T version offering a removable large oil basin and chip tray for portability, and the T version featuring an integrated, larger basin for stationary setups. Both are designed for easy transportation, optimal working height, and stable positioning, whether on a workbench or with various stands equipped with a material shelf.

Packaged in a carton, the REMS Magnum 4 inch Threading Machine is a testament to durable, high-quality engineering for professional threading requirements.

| Description | Set name | Engine/Power | Wattage/Speed | Equipment | Art.-No. |

|---|---|---|---|---|---|

| 4000 L-T | L-T | Universal, 230V/110V |

1700 W, 23 rpm |

R ½ – 2, R 2½ – 4 |

380447 380441 380444 |

| 4010 L-T | L-T | Pole-reversible capacitor, 230V |

2100 W, 20/10 rpm |

R ½ – 2, R 2½ – 4 |

380448 380442 380445 |

| 4020 L-T | L-T | Pole-reversible 3~ induction, 400V |

2000 W. 20/10 rpm |

R ½ – 2, R 2½ – 4 |

380443 380446 |

| 4000 T* | T* | Universal, 230V/110V |

1700 W, 23 rpm |

R ½ – 2 R 2½ – 4 |

380426 380429 |

| 4010 T* | T* | Pole-reversible capacitor, 230V |

2100 W, 20/10 rpm |

R ½ – 2 R 2½ – 4 |

380427 380430 |

| 4020 T* | T* | Pole-reversible 3~ induction, 400V |

2000 W, 20/10 rpm |

R ½ – 2 R 2½ – 4 |

380428 380431 |

REMS Magnum 4-inch is a versatile

high-performance threading machine

When choosing the REMS Magnum 4-inch threading machine, you should consider the following to determine the best variant for your needs:

- Power Source Compatibility:

- Ensure the machine’s voltage requirements match your workshop’s power supply, whether it’s 230 V, 110 V, or 400 V.

- Motor Power and Speed:

- Choose a motor based on the intensity of the workload. A 1700 W motor suffices for standard operations, while 2100 W and 2000 W motors offer more power and dual-speed options for heavy-duty tasks.

- Operational Noise:

- If you require a quieter work environment, consider motors that offer extremely quiet operation, especially those with pole-reversible capacitor or induction features.

- Portability and Stationarity:

- If you need to move the machine around, the L-T variant with a removable large oil basin and chip tray would be suitable.

- For fixed locations, the T* variant with an integrated, even larger oil basin and chip tray is advisable.

- Threading Capabilities:

- Verify the machine’s ability to handle the pipe and bolt sizes you plan to work with.

- Safety Features:

- Look for a machine with a reliable safety foot switch that includes an emergency-stop function.

- Durability:

- A robust body and proven design are essential for longevity and durability, especially in harsh work environments.

- Ease of Use:

- Consider how easily dies can be changed, and if the machine has features like a self-tightening chuck and rear centering device for material alignment.

The variants of the REMS Magnum 4-inch threading machine include models with different motors, such as:

- 4000 L-T: Universal motor, 1700 W, 23 rpm.

- 4010 L-T: Pole-reversible capacitor motor, 2100 W, dual speeds 20/10 rpm.

- 4020 L-T: Pole-reversible 3~ induction motor, 2000 W, dual speeds 20/10 rpm.

- 4000 T:* Universal motor, 1700 W, 23 rpm, with roll grooving capabilities.

- 4010 T:* Pole-reversible capacitor motor, 2100 W, dual speeds 20/10 rpm, with roll grooving capabilities.

- 4020 T:* Pole-reversible 3~ induction motor, 2000 W, dual speeds 20/10 rpm, with roll grooving capabilities.

Choose according to the specific demands of your threading tasks and the electrical specifications of your workspace.

| SKU | Add | Set name | Power | Pipe threads |

|---|---|---|---|---|

| 380447 | L-T | 230V/110V - 50Hz - 1700W | ½ - 2 | |

| 380441 | L-T | 230V/110V - 50Hz - 1700W | 2½ - 4 | |

| 380444 | L-T | 230V/110V - 50Hz - 1700W | ½ - 4 | |

| 380448 | L-T | 230V - 50Hz - 2100W | ½ - 2 | |

| 380442 | L-T | 230V - 50Hz - 2100W | 2½ - 4 | |

| 380445 | L-T | 230V - 50Hz - 2100W | ½ - 4 | |

| 380443 | L-T | 400V - 50Hz - 2000W | 2½ - 4 | |

| 380446 | L-T | 400V - 50Hz - 2000W | ½ - 4 | |

| 380426 | T* | 230V/110V - 50Hz - 1700W | 2½ - 4 | |

| 380429 | T* | 230V/110V - 50Hz - 1700W | ½ - 4 | |

| 380427 | T* | 230V - 50Hz - 2100W | 2½ - 4 | |

| 380430 | T* | 230V - 50Hz - 2100W | ½ - 4 | |

| 380428 | T* | 400V - 50Hz - 2000W | 2½ - 4 | |

| 380431 | T* | 400V - 50Hz - 2000W | ½ - 4 |

- Pending orders

Accessories and options

| SKU | Add | Thumbnail | Products |

|---|---|---|---|

| 3414- | Select |  |

REMS Die set for universal automatic die head 1/16 – 2 inch REMS

|

| Nippelfix |  |

REMS Nippelfix accessories for threading machines

Automatic internal clamping chuck for threading short pipe pieces up to 4″. Quick, tool-free operation, efficient production, internal clamping mechanism, durable clamping. REMS – Made in Germany. |

|

| Nippelspanner | Select |  |

REMS Nippelspanner accessories for threading machines

Nippelspanner is a manual pipe nipple chuck designed for internal clamping of short pipe pieces. Compatible with various threading machines, it saves time and money by utilizing short pipes efficiently. REMS – Germany. |

| REMS Sanitol | Select |  |

REMS Sanitol Thread-cutting oil, made in Germany

mineral oil-free thread-cutting oil, ideal for drinking water pipes and universal threading. Water-soluble, ethanol-free, and featuring high lubrication and cooling effects, it ensures clean threads and longevity of tools. |

| REMS Spezial | Select |  |

REMS Spezial thread-cutting oil, made in Germany

REMS Spezial, an eco-friendly thread-cutting oil, enhances threading with superior lubrication and cooling, extends tool lifespan, and meets environmental standards for safe use on drinking water pipes. Made in Germany. |

- Pending orders